Processing Our Models

Important Information Before Processing Our Models

All our products are a a scale representation of the real thing and may contain small parts that could become a choking hazard. We also advise that our models are unsuitable for assembly by children under the age of 14 years old due to the use of sharp knifes, hazardous glues, small parts or paint products required during assembly.

Processing Our Models

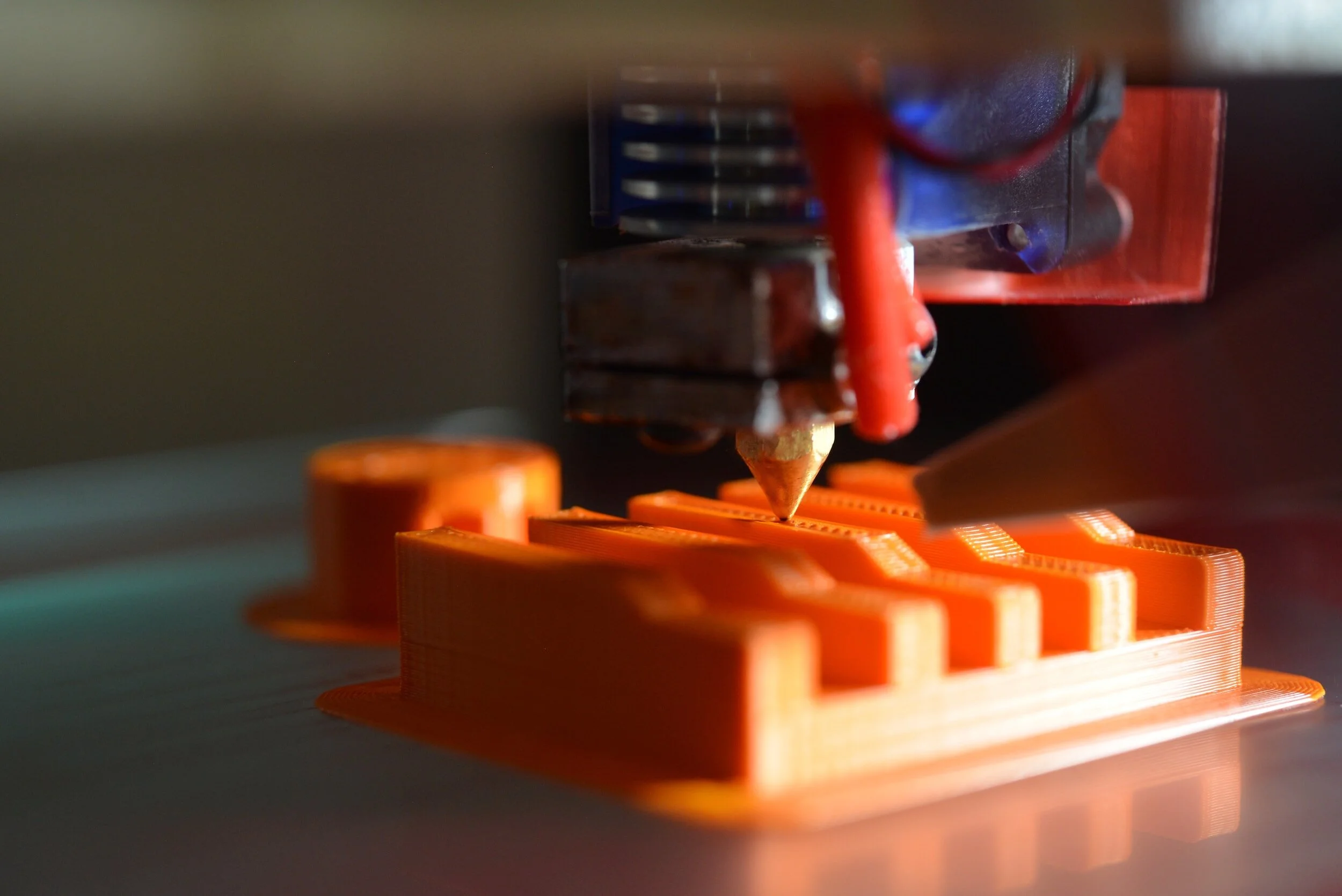

At Fylde 3D Designs we currently use additive manufacturing technologies using Fused Deposition Modelling (FDM) and Stereolithography (SLA).

Our FDM products mainly use PLA (polylactic acid) plastic which is heated to around 180-230 degrees celsius in turn turns molton which can then be easily deposited into layers to make a 3D model. PLA is a relatively safe filament as it’s commonly made from fermented plant starch from corn, cassava, maize, sugarcane or sugar beet pulp.

For stronger parts we use PETG (Polyethylene Terephthalate Glycol). PETG plastic is a type of thermoplastic polyester made from polyethylene terephthalate (PET) combined with glycol to enhance its durability and clarity. Unlike PLA, which is derived from renewable resources like corn starch, PETG is petroleum-based but offers superior impact resistance and flexibility. PETG is more resistant to heat and moisture, making it better suited for functional parts that require durability and longevity. It also exhibits excellent chemical resistance and less brittleness compared to PLA, which tends to be more rigid and prone to cracking under stress. These qualities make PETG a popular choice for applications where strength and resilience are key.

Our other products use SLA technology or more commonly known as resin prints. SLA uses ultra violet (UV) resin chemicals that cure under UV light during the printing process. Resin models can achieve superior levels of details compared to FDM models. Resin is a great option if that model needs extra fine details. Due to the way SLA models are created these require additional post processing with additional chemicals & waste management which can increase costs for production.

What You Need to Consider

PLA plastic has a glass transition temperature of around 60 °C, which means that it starts to soften from this temperature. The material may deform appreciably in the soft state due to even a small force or even deform due to its own weight. When assembling our FDM models its best advised to avoid using hot glue or leaving them on hot surfaces, radiators or using heat guns to dry any paints applied to the model.

Due to chemicals used to produce 3D models with SLA these are very susceptible to UV degradation over time as the resin continues to cure even after the final curing process producing our models. Over time this may make the models become brittle or crack. To avoid any adverse affects we suggest you avoid leaving them in direct sunlight. One solution to reduce this affect we suggest would be applying a layer of paint/ primer to seal model.

Removing 3D Printed Supports From our Models.

As part of the printing process It may be necessary to use supports to print the 3D model. These supports are a byproduct from the printing process and can be discarded. To safely remove the 3D model from the supports start from either the support base or tip and cut each support individually. Then remove each support from the model one at a time until all supports have been removed and discard . After all the supports have been removed from the model, file any remaining spurs with a fine grade sandpaper to a smooth finish.

Please Note: Some models may have delicate parts that can be easily damage, take extra care when removing the supports or filing the spurs from the 3D model.

Painting

We strongly advise that our products are primed using acrylic based primer prior to painting. Once the primer has dried our product are best suited with the use of acrylic based paints manufactured but not limited to Humbrol™, Revell™, Tamiya™ or Vallejo™ to name a few manufacturers to paint the model(s). These paints can be applied by with either an airbrush or with a paint brushes as suggested by the manufacturers or alternatively some manufacturers supply paint in aerosol cans.

Adhesive Compounds

Our FDM & SLA products that we manufacture work well with cyanoacrylate adhesives.

Please Note: We advise against the use of adhesive accelerators as they can have an adverse affect with our models.

Washing Our Products Prior to Painting

This section mainly applies to resin prints; however, you may also wish to clean any FDM prints prior to painting. For resin prints, once all parts have been carefully removed from their supports and any spurs have been sanded smooth, it is recommended to thoroughly wash the part(s) in lukewarm, soapy water. This helps to remove any greasy residue left from the printing process as well as fine dust particles resulting from sanding. After washing, ensure the parts are allowed to dry completely before proceeding with painting. Please note: do not wash any models in boiling hot water, as this will irreversibly damage or deform the parts.

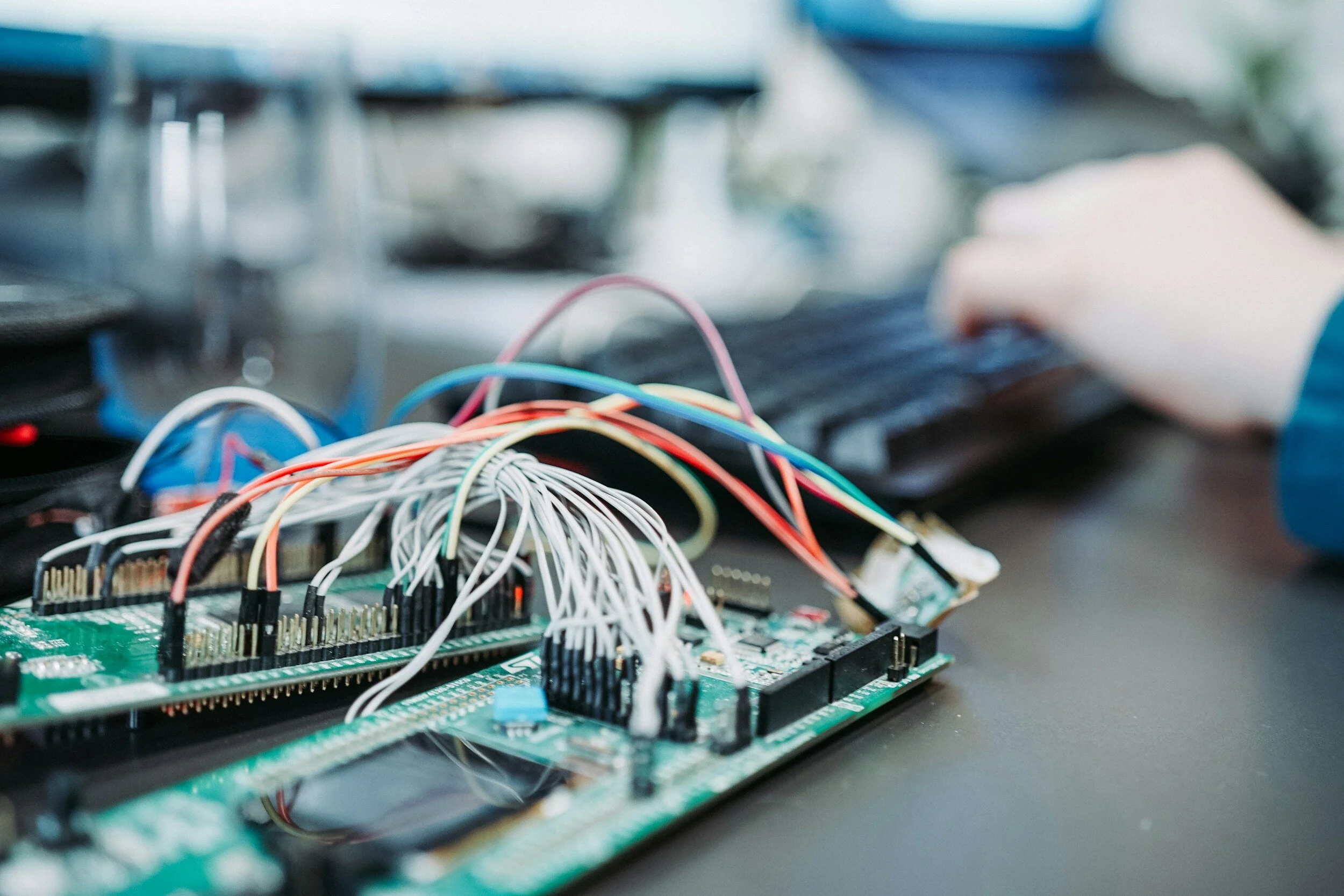

Electronics

Some of our model kits may include electronic components. It is imperative that you carefully read the instruction manual provided before proceeding with the assembly, as the electronics may require specific power supplies or additional components that are not included in the kit. Please be aware that using incorrect voltage or failing to provide necessary components may lead to irreversible damage to the electronic parts. To ensure the successful assembly and operation of your model, we strongly recommend adhering to the guidelines outlined in the instruction manual.

Troubleshooting

All our products are carefully packaged and sorted, however as we are all human, occasionally mistakes will happen and items may arrive damaged due to transit or to a production error not being noticed or occasionally a part may be accidentally not included.

If you find this is the case please contact us at support@fylde3ddesigns.co.uk stating your order number, description of your problem and your contact details and we will be happy to get in touch to resolve any issues.